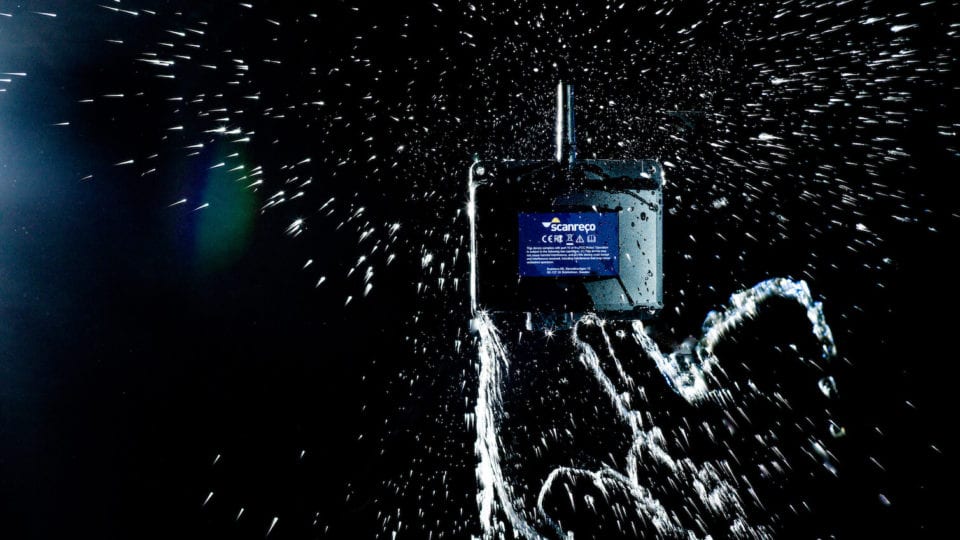

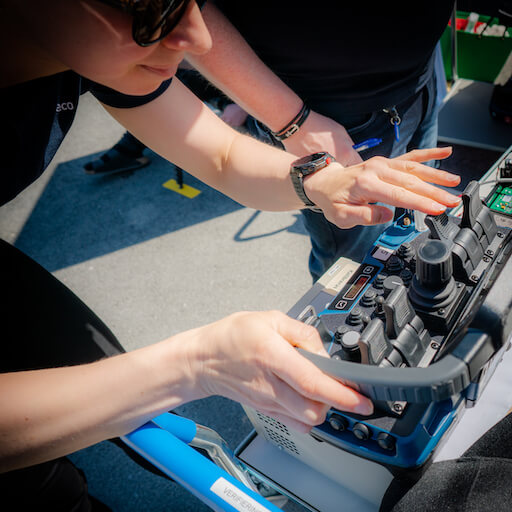

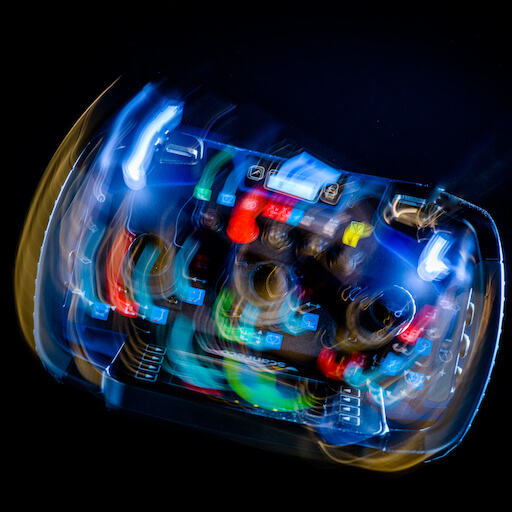

Create your unique custom design remote controls based on our OEM system platforms

If you are looking for a high-volume supplier of custom design remote control systems for professional usage, this is where you find the information – about us and our offering. Never heard about us? We are a global supplier to major OEM:s in various industries (for example Palfinger, Schwing, MacGregor, Demag, Multilift etc). Most of our OEM customers have been with us for decades.