Verification

Data verification process

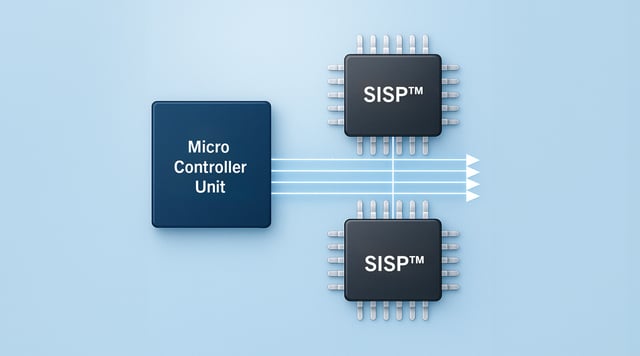

Before the data generated from the actuator movement is transferred to the transmitter's radio module, it undergoes a verification process by a double set of processors on the transmitter mainboard. These processors work in parallel to check the data from several aspects, ensuring both speed and safety. Any minor unexpected deviation will cause the processors to reject the data package before it is transmitted.

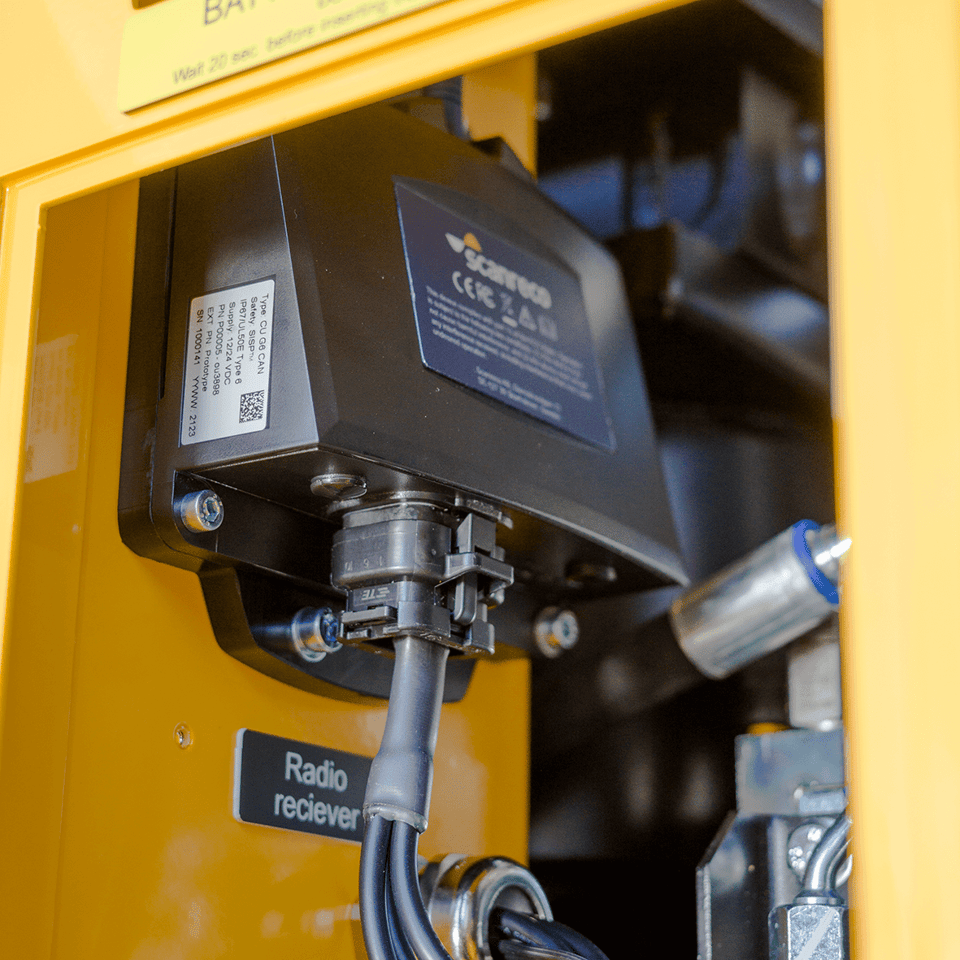

When a command is performed on the transmitter, such as using a joystick or lever to make a movement on the machine, the signals are instantly encrypted before being sent via radio to the receiver on the machine.