Mission & Purpose

Our mission is to provide safe, innovative, reliable, and cost efficient machine control and radio remote control systems. We call this Never-Stop Technology™.

Our control systems are used in the most demanding environments. We partner with machine builders all over the world who rely on solutions that never let their customers down.

At Scanreco we have dedicated almost 40 years to developing a robust radio communication protocol for safe, secure and critical control of machines and heavy equipment such as truck cranes, marine cranes, concrete pumps, demolition robots, drilling riggs, forestry machines, agriculture equipment and many more application types.

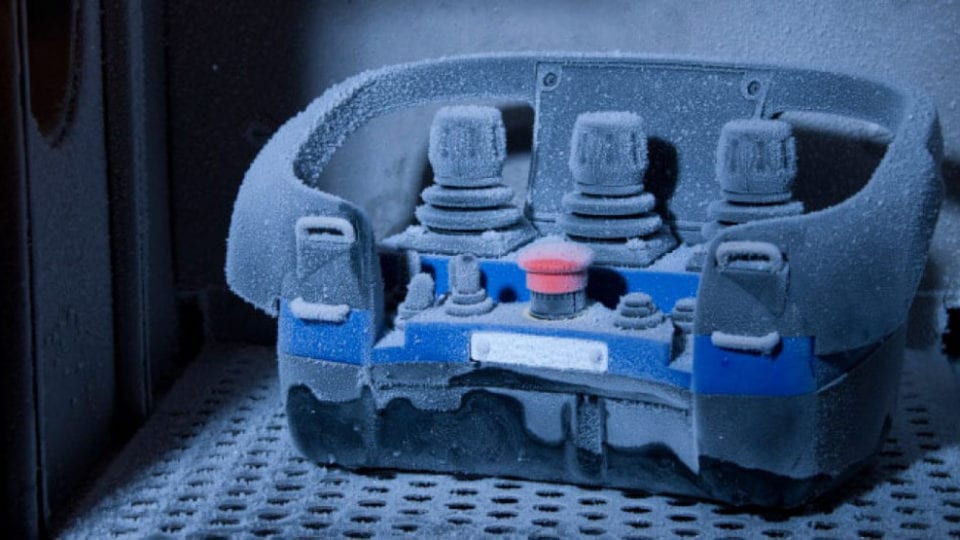

We test our products in the toughest conditions – Watch the Torture Chamber video

Our purpose is to unlock the full potential of the operator in a remote world. We call this Smart Operator.

We help machine builders to develop safe and productive solutions for a new generation operators.

Scarcity of qualified operators and the increasing demand for rental machines, require intuitive and safe radio remote control systems. We help cut operators’ training and education time to a minimum.

In a world with semi or fully autonomous machines, we provide the perfect interface between the operator and your machine – reducing risks, boosting productivity and living up to industry safety standards.

From fishing ships at sea to agricultural sprayers in the field, Scanreco radio remote control systems are tough and built to withstand water, salt, sand, and dust ingress. Let’s face it, the last thing you want to experience is downtime due to water ingress. That is why the leading OEMs in maritime, agriculture and energy equipment depend on Scanreco for long-lasting remote-control solutions.

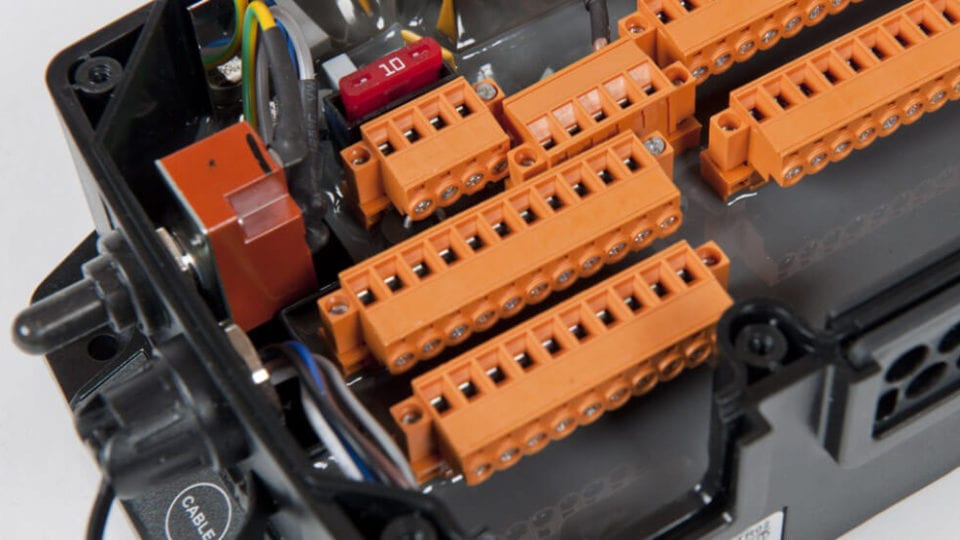

Mobile hydraulic machines vibrate. Machines like stone crushers, horizontal grinders, and conveyors are MADE to vibrate, sometimes violently. Scanreco is the chosen radio remote control platform for mobile hydraulic machines that have the capability to grind concrete, stone, demolition debris, railroad ties, whole trees, pallets, storm debris, shingles, logs, stumps and even entire glass recycle containers. With potted components selected for toughness and durability, our receivers sometimes outlast even the machines on which they are mounted.

Although Scanreco has been a wireless innovator for nearly 40 years, wired connections for tethered control, firmware programming, control box cabling and antenna extensions are sometimes needed. However, we strive to keep wired connection points to a minimum and have designed and reinforced access points to curtail the ingress of water and dust.

Scanreco hardware components like joysticks, paddles, toggles, and buttons are designed for near constant use, day in and day out. Our testing facilities in Stockholm, Sweden include robotic usage simulators that activate these individual components thousands of times per day. Rest assured that the controls on your Scanreco wireless system have the capability to be pushed, pulled, or switched millions of times during their lifecycles.

Scanreco wireless radio transmitters, both belly packs and handheld units, are designed for operator safety and comfort (plus they look really cool too!). Nearly 40 years of radio remote control expertise and customer feedback has provided us with a unique perspective on the ergonomic design of mobile hydraulic remote controls. In addition, Scanreco-specific accessories enable operators to control equipment safely and comfortably all day long in harsh conditions. Mini and Maxi options include neck straps, waist belts, and our ultra-comfortable aluminum carrying hook.

Leveraging nearly 40 years of Radio Frequency (RF) experience, Scanreco’s proprietary Frequency-Hopping Spread Spectrum (FHSS) technology allows you to operate in the noisiest RF environments. Highly resistant to interference, our wireless FHSS technology significantly reduces connectivity drops due to such noise. Additionally, higher RF transmission power options, antenna extension cables, and repeater networks can extend radio coverage into kilometer ranges.

Never-Stop Technology TM by Scanreco is just that: it enables you to finish the job even if your transmitter battery dies. Available only on our Mini and Maxi platforms, you can pop in a fully charged Scanreco battery or run the transmitter via tether cable for as long as you need while recharging.

What sets Scanreco apart from other remote-control manufacturers is our commitment to safety, reliability, ease-of-use, and service. In most cases, Scanreco enables you to replace individual system components and not have to retrofit an entire system. This allows you to:

Scanreco customers demand functionality with minimal failure in nearly all environments: wet, dusty, humid, salty, and extreme cold and hot temperature. From the frigid North Sea to the dusty Texas panhandle, Scanreco radio remote controls are designed to perform day-after-day.

Every job site brings its own unique challenges and things that keep you up at night. Your Scanreco radio remote control should not be one of things you worry about. Although any machine can fail unexpectedly and cause damage to electrical integrations, rest assured that your Scanreco system is built to survive catastrophic machine failures. It may go into hibernation, but it will continue to work.

Fill in your details in the form below, and an expert will get in contact with you.