You can help us unlock the full potential of the operator in a remote world

If you want to outperform your competitors and create the tools that are easy to operate, safe and efficient. This process is for you.

Smart Operator

If you want to outperform your competitors and create the tools that are easy to operate, safe and efficient. This process is for you.

Skill based design is standard in the industry today.This means that an operator might need six months of training to operate for instance a drilling rigg.

Process based design means that the remote assists the operator with information about things they cannot see. For instance, a skilled operator can hear in the steel of the machine how much pressure he/she can apply to the drilling. With information on the remote data can be displayed graphically to reveal resistance etc. This leads to shorter training and a safer control. This is also necessary in a semi and fully autonomous world developing right now.

(All steps are described in-depth in the book “Smart Operator”)

The discovery phases

This is the part overlooked most by the industry. Meet the operator, be with him/her ALL day. Check their reality. Study the working process, where they get the information needed to complete the task. How long did it take them to learn the job? What was the hardest part? Create a “persona” means that you creat an empathic document that describes one person, your target group, the operator.

Your field study will not help you unless you can describe the process flow. This helps you to design the placement of the controls and the information provided on the controller. It is also a must if you are working with semiautonomous machinery.

When choosing platform you need to think about how much the operator is using the controler, how he/she wears it. The placing of the controls and the choice of design is important, especially if you wear a pair of thick gloves.

The Design phases

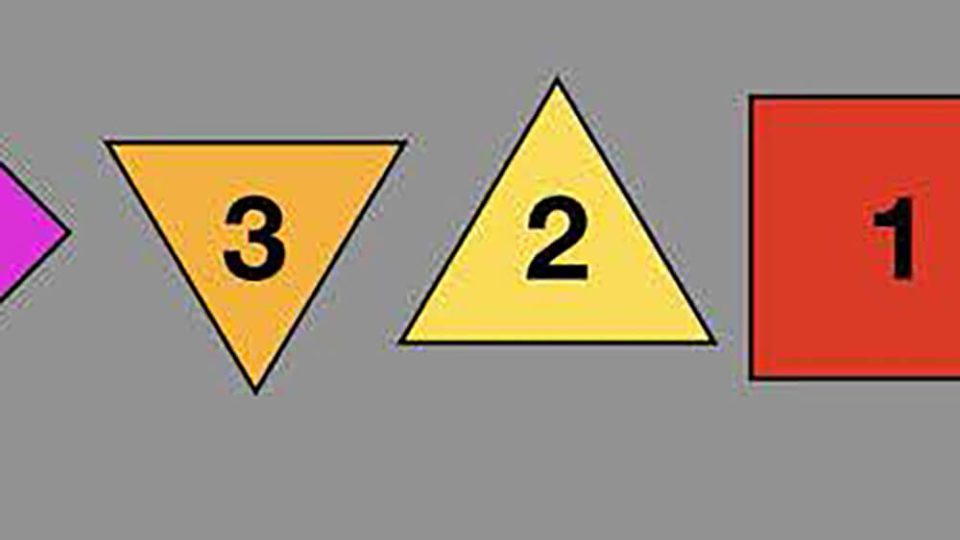

High efficient HMI is about keeping it simple yet provide the information with graphics that tells the operator if something is running smooth or critical. Here you are also dealing with alarm management, something that really needs improvement in many cases.

It might be tempting to rush to the digital tools provided for configuration of the hardware. Reality is always better. Our G6 platform offers 3D cardboard boxes that are replicas of the platforms. Here you can place the controls and get the feel of how it will work in reality (with gloves). We call the kit Quick&Simple. If you are working with another platform, use a shoe box and chess pieces.

Whith a dummy and maybe a powerpoint that shows your information design you can test your ideas on an operator. Make it a workshop and remember to listen well to what he/she might tell you. Redo while it is quick & simple.

Some platforms offer the possibility to design the remote digitally and in 3D. Time to configure your first remote!

If you use a screen to provide information it is time to start programming. But you need also to program the functions to your machine. The system is open for you but you need to know 2 things. One is that some frequencies offer a limited amount of data, so be lean! The other is that we will never let you in to the safety protocols that make sure the signal is safe.

Field test

An exciting moment when it all comes to life!

Make sure you go on site again and check how the operators experience your solution. Even if your buyer is happy you learn more from the operator (again!)

If you made your field studies and checked with the operator during the design phase and followed the first installation to the field you might feel safe. But reality changes and you should make sure there is a way for the operators to report to you how the machine is doing and if there are any problems arising as the system gets used a lot.

There’s no value in the unseen

Wether you are a manufacturer, an integrator or a system engineer the power in your sales is the knowledge your competitor lacks. If you have made the first 3 steps on a competitive machine or remote system you will find so many improvements that need to be done that the buyer has to listen to you.

We know of an integrator that got a deal because they could point at a missing led light that the operator was missing.

We have distributors in many countries, covering almost all continents of the world. Find the nearest distributor below.

Fill in your details in the form below, and an expert will get in contact with you.